CFD analysis – Industrial baking oven

Transheat scope

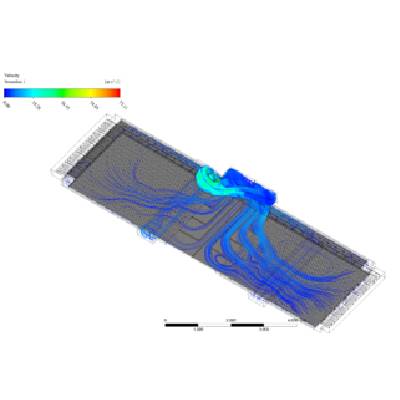

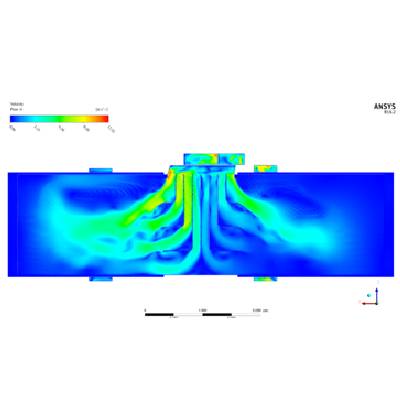

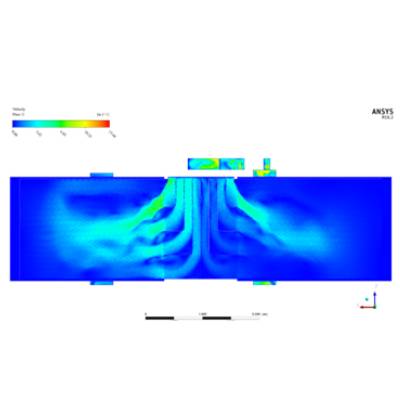

Study the secondary circuit air flow / velocity profile inside the baking chamber of an industiral baking oven.

Installation in :India.

All design documents reviewed by : PDVSA, Venezuela and ASME AI.

Major design attributes

To establish the air flow path, velocity and pressure profiles at various locations within the secondary air circuit of the oven chamber.

Air flow rate generated by the fan in this secondary circuit and the power consumption by fan are also established as an outcome of this analysis.

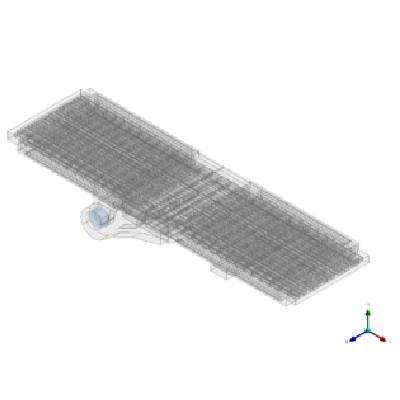

- 3D model of the secondary air circuit including the fan model is given by client

- Fan speed = 1900 RPM

- Air temperature = 220oC

- Air density at operating conditions = 0.746 kg/m3

- Effects of heat and mass transfer (moisture removal) are not considered in analysis.

Velocity and pressure profile plots at different planes / locations in the chamber are extracted after post-processing.

Secondary air circuit is considered as a closed loop system. The fan sucks air from the chamber and forces it back into the chamber.

Oil flow velocity, flow pattern (laminar / turbulent / fully developed) and heat transfer data are calculated based on the resulting flow pattern due to the closed loop.