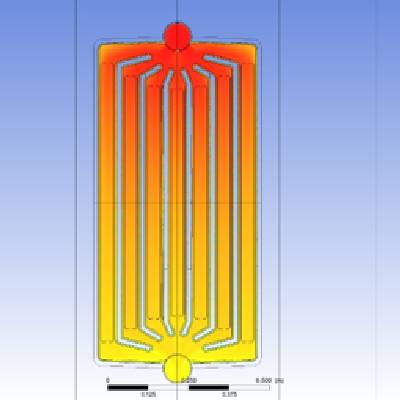

CFD analysis – Radiator plates in a transformer system

Transheat scope

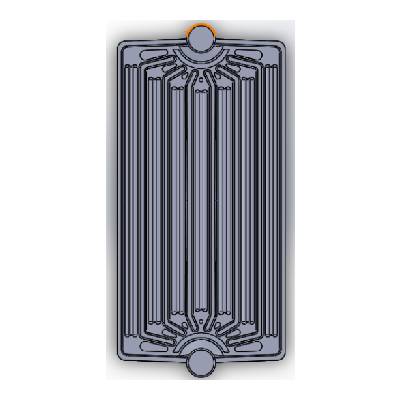

CFD analysis setup, boundary conditions, the input parameters, analysis outputs and comparison of performance results between the two radiator plate models – 7 flute and 9 flute designs, both with 1000 mm center distance between top and bottom headers. All analysis is done considering mineral oil as the heat transfer fluid. Oil flow inside the header and radiator plates is by natural circulation only (no pumps). Air flow outside the radiator plates is also by natural circulation only (no fans). Comparison of the performance predicted by CFD analysis and the performance as per experimental data for the 7 flute design

Installation in : For a radiator manufacturer in India.

All design documents reviewed by : PDVSA, Venezuela and ASME AI.

Major design attributes

- Variation in physical properties of fluids considered for analysis.

- Simulation for natural convection flow and temperature profile.

- Tank (or mineral oil reservoir) modelled as per the client data.

Mineral oil circulation through the closed loop system is only due to static head, temperature variations and resulting density differences.

Analysis is continued till the variation of temperature with respect to time at the inlet and outlet headers is very marginal / negligible.

Oil flow velocity, flow pattern (laminar / turbulent / fully developed) and heat transfer data are calculated based on the resulting flow pattern due to the closed loop.