Finite Element Analysis-Dish-Skrit Junction for Hot Box of Decoker Drum

Transheat scope

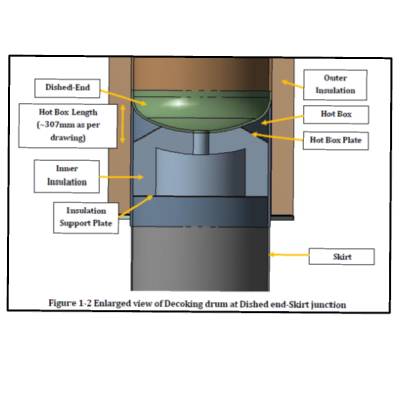

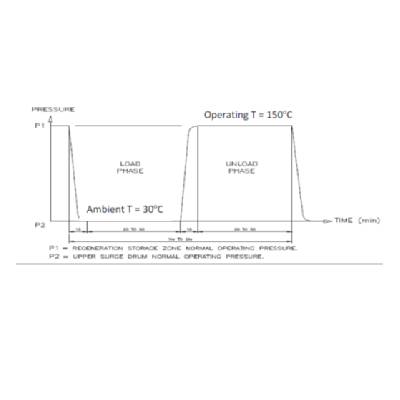

Performing Static structural analysis to calculate the displacements, stresses, strains, and forces in structures caused by loads under steady loading conditions. Perform steady state thermal analysis to study temperature profile in the skirt and a linear elastic analysis to study the deformation and stress distribution in Decoking drum at Shell – Dished head – Skirt junction for pressure, temperature and other external loading conditions. Identify optimum length of hot box to obtain minimum stress generation at the junction and symmetrical temperature profile across the skirt.

All design documents reviewed by : ASME AI.

All design documents reviewed by : PDVSA, Venezuela and ASME AI.

Major design attributes

- Design temperature = 620oC

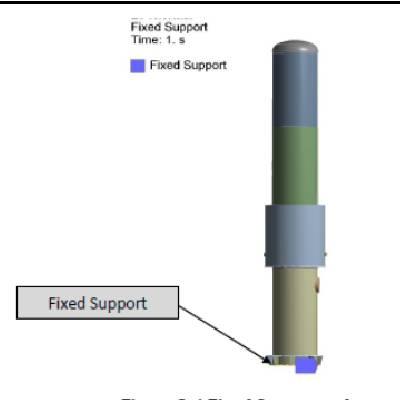

- Create a three-dimensional solid model of Decoking drum with support.

- Import 3D solid model in ANSYS and create appropriate mesh in ANSYS .

- Assign the specified materials to the model.

- Apply the specified loads to the model.

- Introduce the geometrical boundary conditions and constraints.

- Observe the results and compare it with design criteria per design code.

- Consideration of air convection on inside and outside surfaces at hot box

- Consideration of radiation / surface emissivity at hot box location.

- Stress classification lines and linearization performed.