Finite Element Analysis of LP Fuel Gas Suction Bottle

Transheat scope

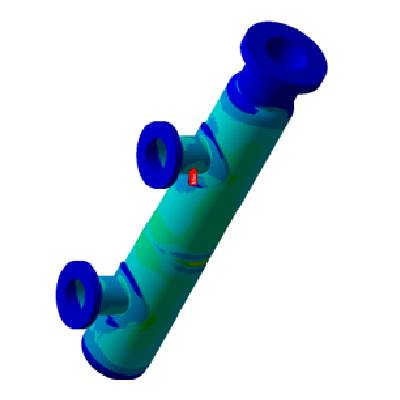

Perform a Finite Element Analysis (FEA) for the complete vessel to ensure that stresses within the vessel components due to the specified design and test conditions are within the code allowable limits

Installation in : For a client in UAE

All design documents reviewed by : ASME AI.

Major design attributes

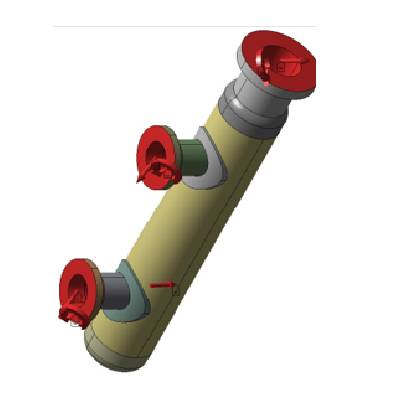

Due to small size of suction bottle, no separate supports are provided. Nozzles act as supporting elements for the suction bottle boundary conditions and load cases evaluated.

- LP Fuel gas suction bottle is a horizontal shell with standard end caps on either side.

- A gas inlet nozzle is provided on one of the dish heads to facilitate entry of gas.

- Two nozzles are provided on shell to facilitate supply of gas to the different stages for further processing.

- Specified nozzle loads are applied at the flange face of each nozzle.

- Stress linearization as per the design code requirements.

Since there is no fixed support point in the vessel, the centre of shell is condisered as a fixed point for the purpose of this analysis.

Maximum stresses in vessel for specified design and test conditions along with applicable loads are evaluated as per the rules of ASME Sec. VIII Div. 2 Part 5.

Design Pressure = 6.21 MPa.