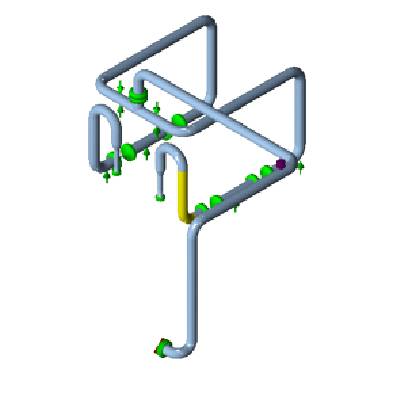

Hot oil supply and return piping

Transheat scope

Study the existing closed loop hot oil system supply and return piping and suggest measures to avoid repeated failures of mechanical seal and pump shaft which was resulting in plant downtime and huge production losses. Hot oil temperature at exit of hot oil heater is 300oC.

Installation in : At a chemical and fertilizer plant in Vadodara, India.

All design documents reviewed by : PDVSA, Venezuela and ASME AI.

Problems identified in existing system

Hot oil supply and return pipe routing was done without due consideration of the pipe behavior at elevated temperatures Supports located in the hot oil piping system were not selected properly.

Proper stress analysis of the hot oil piping network was not carried out.

These deficiencies lead to huge piping reactions at the hot oil pump suction and discharge nozzles and consequently failure in the hot oil pumps.

The suggested modifications were implemented by client (under Transheat supervision) and the system is now operating continuously.

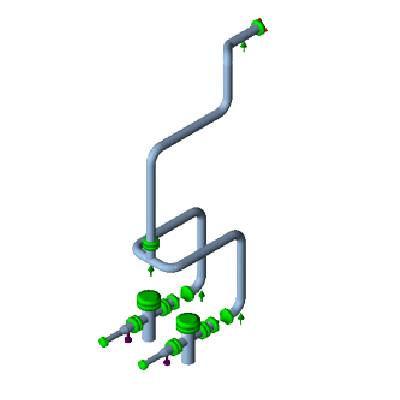

Solution implemented as per Transheat recommendations

Changes in pipe routing and supports keeping many site constraints in view of the existing plant layout

Provided spring hanger supports in the hot oil pump suction piping These modifications maintained adequate flexibility in the piping system and ensured that the piping reactions at the hot oil pump suction and discharge nozzles were well within the limits recommended by the pump supplier.