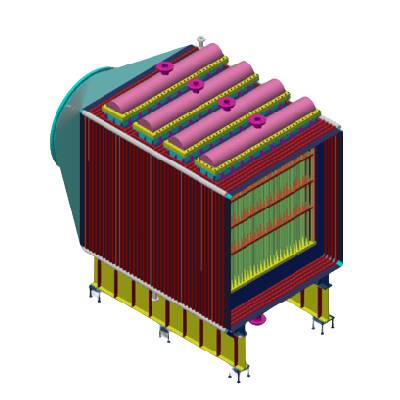

Gas Cooler with HP water wall panel and D-type header tube bundles (HPGC)

Transheat scope

Mechanical design of Gas Cooler with HP water wall panels and tube bundles with D-type header for water inlet and outlet connections, FEA of expansion joints, inlet and outlet ducts for flue gas, structural design, 3D modelling, complete fabrication drawings for unit and support strucutres.

Installation : At a speciality chemicals facility in India

All design documents reviewed by : TPI / Client

Major design attributes

- ASME U-Designator for tube bundles and water wall pressure parts.

- Multiple D-type header tube bundles inside the water walls.

- HP Water (42 bar(g)) on tube side including water walls.

- Finned tubes to enhance heat transfer efficiency.

- Varying fin density (FPI) in the tube bundles as per requirement.

- Flue gas on shell side with horizontal flow.

- High flue gas inlet temperature (> 800 C).

Units wSupport legs with appropriately sized slotted holes. Material : Tube bundles with D-type header in Carbon steel & fins in SS316, water wall in SA 204 / 16Mo3 steel to suit high temperature.ith complex internal arrangements (like separator vessels) are modelled completely in SolidEdge / SolidWorks and drawings generated from the same model.

Complete equipment with support structure and expansion bellow modelled in 3D, fabrication drawings and MTO from same model.

Software used for detail engineering :

In-house excel calculation sheets, STAADPro, Advance Steel, ANSYS.