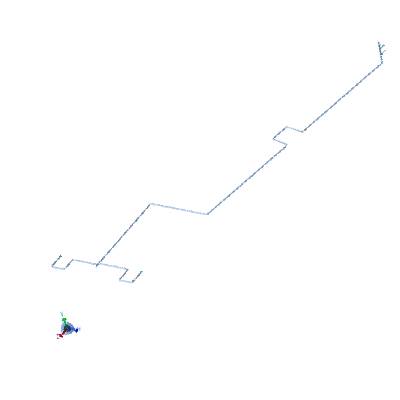

Piping stress analysis – Turbine suction piping

Transheat scope

Study the existing turbine inlet piping system and suggest measures to avoid turbine tripping due to excessive vibration at turbine.

Installation in : At a chemical and plant in Madhya Pradesh, India.

All design documents reviewed by : PDVSA, Venezuela and ASME AI.

Client reported excessive vibration in the turbine after startup of the unit. This led to repeated tripping of the turbine and plant downtime.

Transheat studied the existing piping system – from the superheater to the turbine inlet and suggested modifications in the piping routing and support (type and locations) to ensure that the forces and moments at the turbine nozzle were well within the turbine supplier specified limits. Required specifications for the spring hanger supports were provided and vendor offers were evaluated for acceptance.

The suggested modifications were implemented by client (under Transheat supervision) and the system is now operating smoothly with vibration levels within the allowable limits.